No.131, Changning Road, Beiyang Town, Huangyan District, Taizhou City, Zhejiang Province 400-1850-999 [email protected]

Introduction to the Heat Transfer Printing Process

Heat transfer printing is a sophisticated and versatile decorative technique that has revolutionized surface finishing across numerous industries. At its core, it is a multi-stage process that begins with digital or artistic design and culminates in the permanent fusion of that design onto a product. The journey starts with the creation of a pattern. This design is then used to fabricate a precision copper plate, often through a photomechanical process. Subsequently, an electro-engraving machine meticulously engraves the pattern onto this copper plate. For multi-colored designs, separate cylinders are typically engraved for each color. This master cylinder is then mounted onto a high-precision printing machine, which applies the individual ink colors onto a specialized heat transfer film, building up the complete pattern layer by layer.

An alternative method involves using a coating machine to uniformly apply ink onto the heat transfer film according to the pre-set digital graphic. Regardless of the printing method used to create the pattern on the film, the final and most critical stage is the transfer itself. This is accomplished using a heat transfer machine, which uses a combination of controlled heat and pressure to lift the pattern from the carrier film and bond it permanently onto the surface of the target product.

Traditional Applications and Material Limitations

Within existing industrial applications, heat transfer printing has established itself as a premium finishing method for a wide array of materials. Its use is prevalent on various plastics, including ABS, AS, PS, PVC, EVA, PP, and PE, as well as on fabrics, ceramics, and metal-coated board products. The appeal of this technology lies in the superior quality of the finished product. It offers exceptional adhesion and wear resistance, ensuring the design withstands handling and use. Furthermore, the inks used are formulated for excellent sun resistance, preventing rapid fading. The resulting patterns are remarkably realistic and bright, with an ink surface that is uniform, smooth, and fine, free from the texture or unevenness associated with other printing methods like screen printing.

However, the application of this technology has historically been constrained by the surface properties of the substrate. For adhesion to be successful, the ink must form a strong mechanical and/or chemical bond with the material. Traditional heat transfer printing excelled on substrates with a specific surface profile but faced significant challenges with materials like glass. Glass substrates are characterized by an extremely low surface roughness (typically in the range of 0.5 to 10 nanometers) and a very high gloss. While these properties are desirable for clarity and appearance, they create a surface that is inherently non-porous and slick. The ink-like materials used in traditional heat transfer processes struggled to achieve sufficient adhesion on such a smooth surface, often leading to peeling or scratching. Consequently, for many years, heat transfer printing was not considered a viable option for decorating glass products.

The Breakthrough: Adapting Heat Transfer for Glass

The primary method for decorating glass products has long been screen printing. While effective for simple, solid-color designs, screen printing has inherent limitations. It struggles with achieving highly detailed, photorealistic images, smooth color gradients, and perfect registration in multi-color designs. The process can be cumbersome, with each color requiring a separate screen and a separate pass through the printer, increasing the time, cost, and potential for error.

Recognizing these limitations, innovators in surface decoration sought to adapt the heat transfer process for glass. The breakthrough came through the development of specialized transfer films and adhesive layers engineered specifically for low-surface-energy materials like glass. By reformulating the ink chemistry and the crucial adhesive layer, manufacturers created a system that could activate under a specific heat and pressure profile to form a tenacious bond with the smooth glass surface. This improved process directly addresses the flatness, fineness, and adhesion requirements that screen printing could not consistently meet, thereby fulfilling the stringent quality demands for high-value products in specialty markets, such as premium perfume bottles, pharmaceutical glassware, and high-end decorative glass items.

The Operational Workflow and Structural Advantages

The refined operational process for glass heat transfer printing is a streamlined sequence:

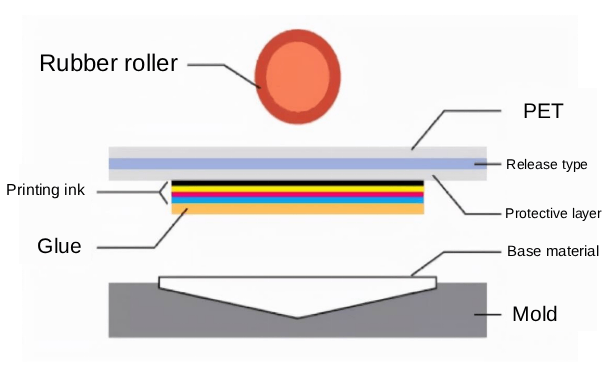

The heat transfer film itself is a marvel of material engineering, typically composed of five distinct layers. The base is a PET film layer that acts as a stable, flexible carrier throughout the process. Above this lies the release layer, which is designed to melt or soften at a specific temperature, allowing the subsequent layers to cleanly separate from the PET carrier. The protective layer is a transparent coating that safeguards the printed image from abrasion and UV light. The ink layer contains the actual patterned image. Finally, the adhesive layer is the critical component for glass applications, formulated to flow and create a powerful bond with the smooth glass surface upon heating.

Comparative Advantages Over Screen Printing

The benefits of this adapted heat transfer printing for glass are profound, especially when compared to traditional screen printing.

In conclusion, the adaptation of heat transfer printing for glass products represents a significant technological advancement. By overcoming the historical challenge of adhesion on low-surface-energy materials, it has unlocked new possibilities for decorating glass with unprecedented levels of detail, color vibrancy, and efficiency. As material science continues to advance, the scope of heat transfer printing is poised to expand even further, solidifying its role as a cornerstone of modern industrial decoration.

Hot News

Hot News2025-09-26

2025-08-21

2025-07-24

2025-06-26

2025-05-23

2025-04-24